| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : SDN

Model Number : SDN filter thickener - Generation 4 (A)

Place of Origin : Chengdu, Sichuan

Advantage 1 : Advantages of the same metal filter element

Advantage 2 : No stirring risk point

Advantage 3 : The equipment is small in size

Advantages : Large processing capacity, small footprint, easy maintenance

After-Sales Service : Engineers available to service machinery overseas

Application : Dewatering and solid-liquid separation

Capacity : 10-2500t/d

Control System : Manual, semi-automatic or automatic control

Depth : 1.8-5.4m

Diameter : 3-20m

Features : High efficiency, low energy consumption, stable operation

Installation : Can be installed horizontally or inclined

Material : Carbon steel or stainless steel

Model : NZSG

Motor Power : 3-22kw

Scope Of Application : Mineral processing, metallurgy, chemical industry, coal, non-metallic ore, environmental protection, etc.

Structure : Central drive, peripheral drive or bridge type

Working Principle : The slurry is fed into the center of the thickener and slowly moves towards the periphery, while the clear liquid overflows from the top. The settled solids are discharged from the bottom.

MOQ : 1 PC

Price : Negotiable

Packaging Details : Customizable packaging

Delivery Time : 7-30days

Payment Terms : L/C, T/T

SDN filter thickener

Generation 4(A)

Main feature

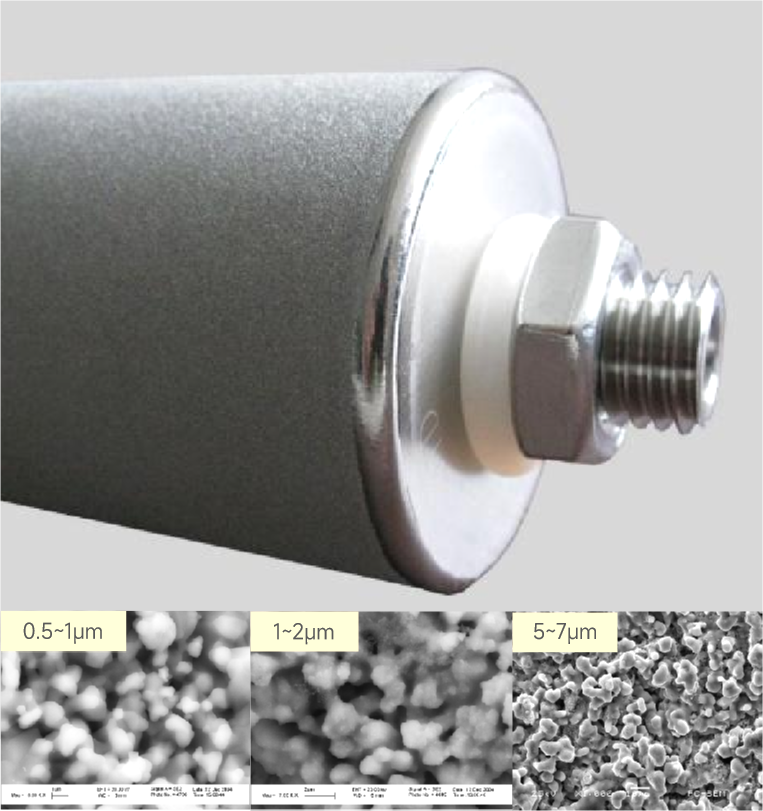

· Titanium-based metal filter element

· Threaded installation and double-end fixing

· Stirring power is provided by circulating pump without stirring paddle

· Positive pressure clearing

Main advantages

1. Advantages of the same metal filter element

2. No stirring risk point

3. The equipment is small in size

Main process

No intermediate kettle

Reaction kettle → Feed pump → 4 generation machine → Reaction kettle

There is an intermediate kettle

Reaction kettle → Intermediate kettle → Feed pump → 4 generation machine → Reaction kettle

Introduction to filter elements of SDN thickener

01 Productive process

Industrial high purity metal powder as raw material, by high pressure pressing, high temperature sintering production. Joints are welded with inert gas protection without any adhesive.

02 Material characteristics

a) It is the first to prepare membrane materials by Kirkendall effect caused by partial diffusion between elements;

b) Reaction synthesis technology can realize precise regulation of pore structure at micron/submicron level, uniform pore size distribution of materials, high filtration accuracy, high open porosity, small tortuosity factor and small filtration resistance;

c) The unique mixed bond crystal form of "metal bond + covalent bond" combines the advantages of metal and ceramic materials, and has excellent chemical stability, thermal stability, mechanical and physical properties, machinability, thermal conductivity and electrical conductivity;

d) Material preparation process, environmental protection, friendly life cycle, recyclable and cost-effective.

|

|

Metal Filter Thickener Small Footprint Industrial Filter Equipment Images |